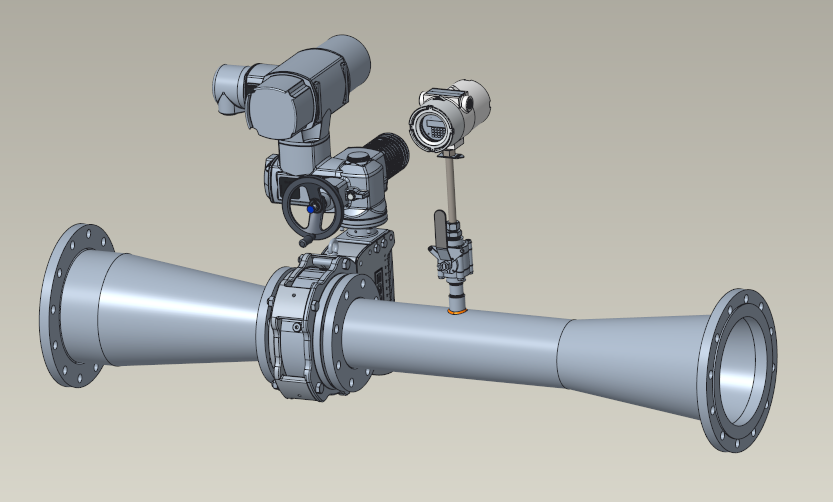

IRIS® Measurement Regulation System

Constant Pressure & Flow Regulator

PRESSURE CONTROL – LIQUID OR GAS

FLOW CONTROL – LIQUID OR GAS

High Performance Constant Pressure & Flow Regulator

Available Sizes: 1″ – 16″

Pressure: up to 87 psi higher upon request

Temperature: up to 248 higher upon request

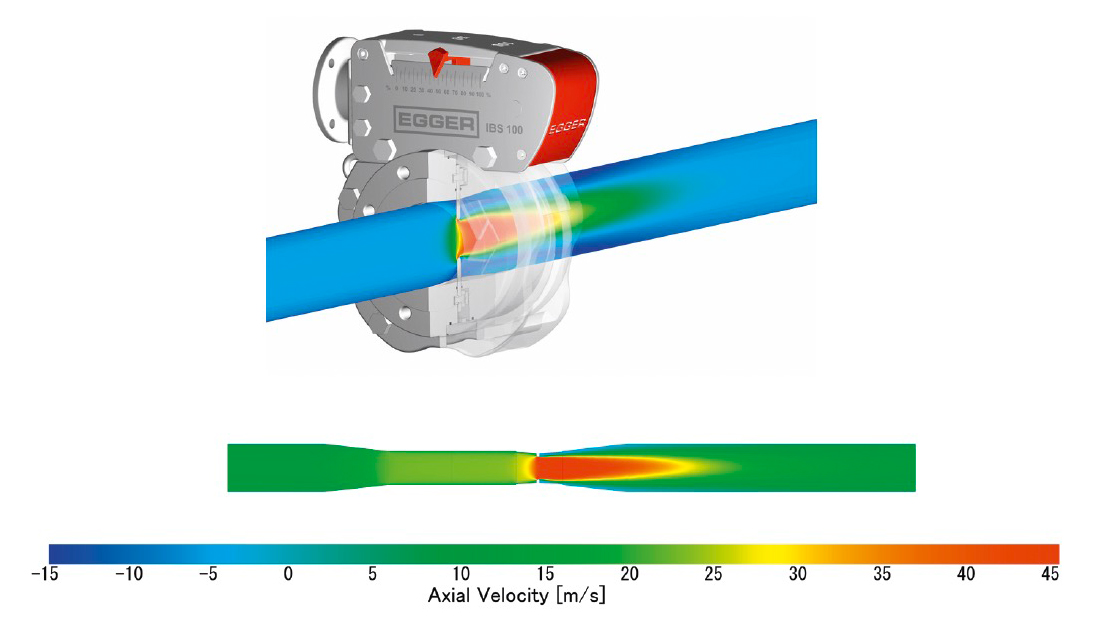

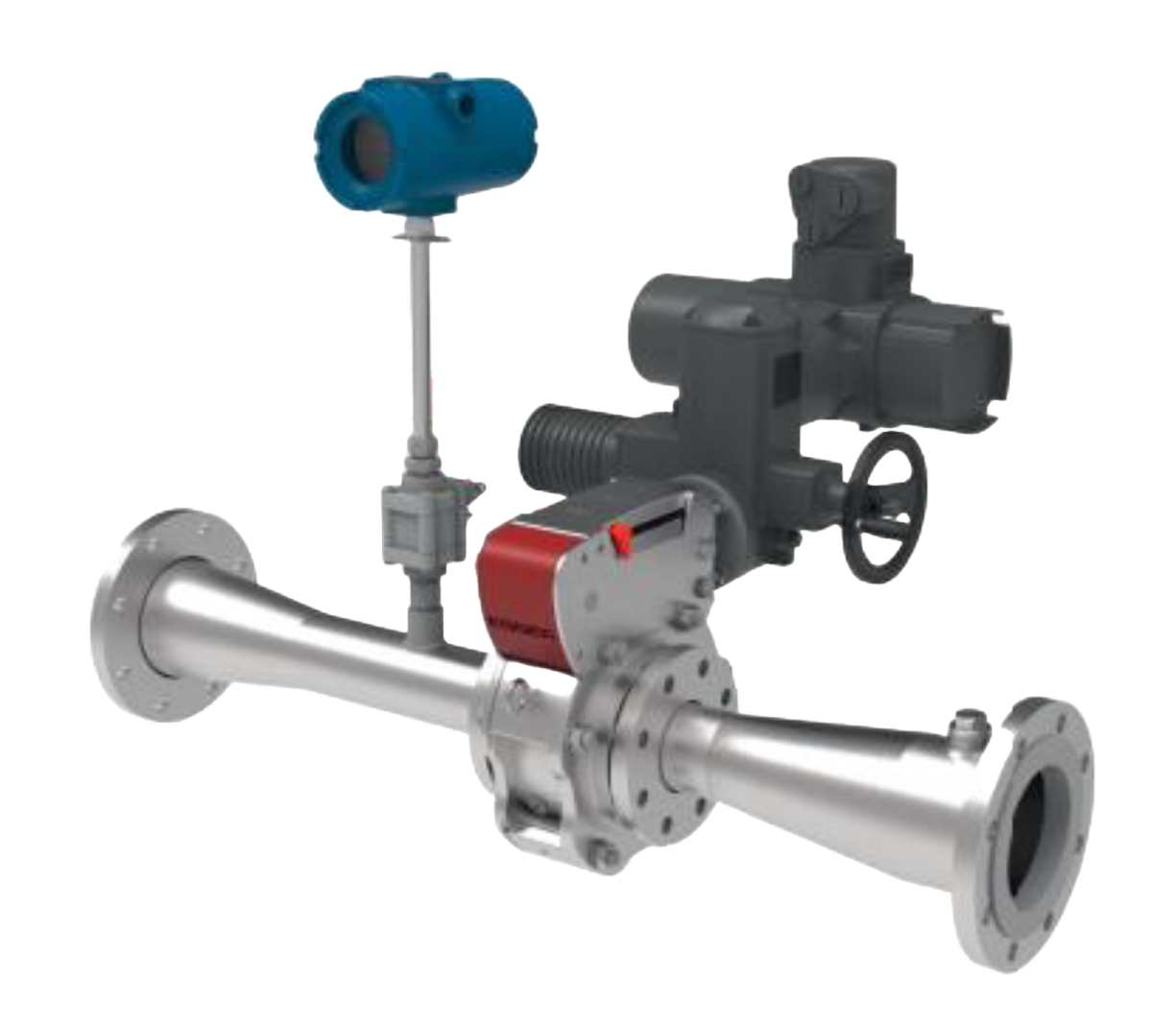

For fast, accurate and repeatable measurement and control of gases and liquids. The high-precision and fast-response mass fl ow measurement with sensor in the center of the flow axis guarantees precise and reproducible measured values without correction. Retractable segments in the housing allow free flow when the valve is fully open, ensuring low pressure losses and high energy-saving potential.

Energy Cost Saving and Low Noise Emissions

Due to the free passage and low turbulence in our Constant Pressure & Flow Regulator, energy costs and noise emissions are reduced to a minimum.

Rugged, Heavy Duty Construction

Designed for continuous operation, particularly suitable for variable duties. Simple installation and commissioning.

Non-clogging and self-cleaning

Due to the free, central flow design and automatic self-cleaning feature of the segment edges during valve operation Flushing connections are provided.

Several actuator designs available

Electrical actuator for precise regulation permitting up to 1200 operations per hour. Optional pneumatic actuator, hand wheel or lever.

Hysteresis-free and excellent regulation characteristics

These are the prerequisites for regulating tasks. This is achieved by the continually variable aperture from 0-100%, similar to the IRIS diaphragm of a camera, always maintaining a central flow axis and by an enhanced segment edge design.

Various fields of applications

The iris flow control flow regulator may be used for liquids, gases, granules or powders. Available with integrated flow measurement for gases.

EGGER TURO PUMPS N.A. imports the Iris technology from Emile Egger & Cie SA, and we assemble our packaged system in Juliette, Georgia. Our monitoring & control system is comprised of the following components:

- Iris technology (purchased from Switzerland).

- AUMA gear-drive electric actuator (U.S. manufactured in Canonsburg, Pennsylvania).

- Kurz thermal mass flow meters (U.S. manufactured in Monterey, California).

- Felker Brothers piping (U.S. manufactured in Marshfield, Wisconsin).

- Final assembly & calibrated in Juliette, Georgia.

EGGER TURO PUMPS N.A. is the only manufacturer in the world who designs, builds, & markets Iris Measurement & Control System.

We ensure domestic component costs exceed 55% of the cost of all components. Therefore, no federal waiver is required in association with the use of solutions.

DO Based Aeration Control with diffused aeration and blowers

• IRIS Constant Pressure & Flow Regulator for:

– Airflow based control

– Pressure based control

• Most Open Valve automated control types

• Ammonia-Based Aeration Control (ABAC)

Let us help you with your application.

EGGER IRIS® MRS Measurement Regulation System

NEWS & UPDATES

Build America / Buy America Act Conformance Statement

EGGER TURO PUMPS N.A. manufactures the “Iris Measurement & Control System” specifically designed for the municipal wastewater industry. Our control system optimizes the control of dissolved oxygen to the biological nutrients to ensure proper control of the aeration...

Low Dissolved Oxygen Control

IRIS Control Valves can play a crucial role in Low Dissolved Oxygen Control by helping to regulate oxygen levels in water treatment and distribution systems.

Ammonia Based Aeration Control

The IRIS Control Valve can play a critical role in helping with ammonia based aeration control by providing precise control over the airflow to the wastewater treatment process. Here are some ways in which the IRIS Control Valve can help: Accurate Airflow Control: The...

EGGER IRIS® Featured in Process Technology & Components 2022

The EGGER IRIS® Process Control Valve was featured in Process Technology & Components 2022, independent Independent magazine for Pumps, Compressors and Process Components.

Positioning accuracy of Iris Diaphragm Control Valves under real conditions

At the Brightwater wastewater treatment plant in King County, Washington State, northeast of Seattle, 12 Iris® Diaphragm Control Valves are used for the airflow control of the aeration tanks. Nine 8” Iris® valves control maximum air flows of up to 4000 SCFM (6500...

New Iris Diaphragm Control Valve IBS

We are driven by a desire to make the tried-and-tested increasingly better. Thanks to systematic further development, Egger is proud to launch a completely redesigned and technically revised Iris® diaphragm control valve onto the market; we name the new model...

DESIGNS

As Process Engineers begin changing their processes to “Low D.O.” and/or “ABAC” systems,

they have found that the IRIS Flow Regulator is the only product in the market which can provide stable control at the high flows as well as at 5% or 10% Open (Low Flows).

Simply, IRIS is the only flow regulator with constant geometry from 0 to 100 percent.

1947: Swiss Engineered Pumps

EGGER, founded by Mr. Emile Egger, is an independent family-owned Swiss pump manufacturer specializing in handling solids and aerated liquids.

A key quality feature is that the whole production process – from development through functional testing – is carried out in-house under controlled conditions by 350 skilled employees.

Thanks to the contribution of each member of our team, we have succeeded in maintaining our excellent level of quality; the highest even by typical Swiss standards.

Our unique background has been achieved by our ability to identify with and listen to each of our business partners. These partners have many different specific needs, however, all can be sure of

one thing: EGGER has the unique solution for them.